Marine

Improve passenger comfort while reducing vehicle weight

Marine insulation systems based on SOLIMIDE® foams are used as thermal and acoustical vessel insulation on marine vessels around the world. The inherent nonflammable property of SOLIMIDE® foam translates into a significant reduction in fire load for the insulation.

Whether the marine application is military or commercial, literally tons of topside weight can be saved when SOLIMIDE® foam replaces heavier fibrous insulation in such applications as hull board, duct wrap and acoustic ceiling panels. More than 15 navies and many commercial operators around the world use SOLIMIDE® foam marine insulation systems on their vessels.

Applications:

Naval Marine:

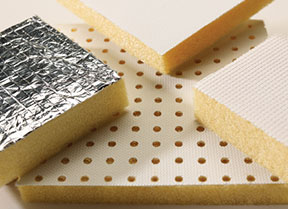

Navies around the world have chosen SOLIMIDE® foam as thermal and acoustic insulation for their vessels and saved literally tons of topside weight by replacing heavier fibrous glass insulation with SOLIMIDE® foam. The lightweight, inherently fire-resistant foam can be fabricated into multiple marine market products in sheet form or cut into a variety of shapes or sizes, then faced or coated to meet end-user requirements.

SOLIMIDE® thermal laminate: glass cloth laminated to SOLIMIDE® thermal insulation foam

Lightweight replacement for MIL-I-742 thermal hullboard insulation.

Weight of SOLIMIDE® Thermal Laminate: Nominal 0.15 lbs/ft2 (0.73 kg/m2) at 1" (25 mm) thickness.

SOLIMIDE® acoustic laminate: glass cloth laminated to SOLIMIDE® acoustical insulation foam

Weight of SOLIMIDE® Acoustic Laminate: Nominal 0.14 lbs/ft2 (0.68 kg/m2) at 1" (25 mm) thickness.

Noise transmission loss blanket

Glass cloth laminated to SOLIMIDE® acoustical insulation foam. Lightweight blankets available using various septums in a wide variety of configurations.

Acoustical ceiling panels

Attractive lightweight (0.32 lbs/ft2 or 1.56 kg/m2) ceiling panel, designed to fit standard 2'x2' or 2'x4' T-bar grid system. Provides excellent acoustics along with fire-safety, durability, and easy ceiling access.

Duct liner

SOLIMIDE® foam with a smooth surface can readily be inserted into ducts for internal thermal/acoustical treatment. This provides an insulating system that is light, effective, resistant to open flame and does not require a protective or vapor barrier covering.

Pipe covering

SOLIMIDE® foam shaped for easy installation as pipe covering. Reinforced aluminized polyester/aluminum foil vapor barrier and/or ceramic glass cloths are easily laminated to SOLIMIDE® foam.

Duct wrap

SOLIMIDE® foam faced with reinforced aluminized polyester/aluminum foil vapor barrier or with glass cloth laminated to reinforced aluminized polyester/aluminum foil vapor barrier for use as lightweight, nonflammable duct wrap.

Commercial Marine:

SOLIMIDE® TA-301 and HT-340 foams are certified as fire-restricting materials in accordance with the International Maritime Organization (IMO) High Speed Craft code. Both high-speed yachts & ferries utilize SOLIMIDE® foam to maximize weight-to-performance ratio while maintaining fire safety. LNG tankers also employ SOLIMIDE® foam in their expansion/contraction joints because of its excellent recovery properties at cryogenic temperatures.

Weight savings, fire safety, and superior performance are achieved using SOLIMIDE® foam alone or in combination with other materials, for insulation on commercial marine vessels.